Pumping Heat

Only a few years ago electric cars were viewed as a novelty. Something that worked but did not appeal to the masses because of perceived shortcomings and limitations. The same can be said for heat pumps. Just like electric vehicles, heat pumps have existed for decades, worked fine with a few notable drawbacks, and had a strong but small following. An air-to-air heat pump is essentially an air conditioner running in reverse. Imagine taking a window air conditioner and installing it backwards - blowing the cold air outside and the warm air inside.

As simple as it sounds, the process has (or had) limitations. As it gets colder outside it becomes harder to absorb heat from the outside air. Older systems usually worked well when temperatures stayed above freezing but rapidly lost capacity as it got colder and needed inefficient supplemental heat to keep up with the heating demand. These older systems are still in widespread use across the southern United States where they encounter only a handful of sub-freezing nights every year.

In the past 15 years, foreign equipment manufacturers have made huge strides in improving the operating characteristics of heat pump systems. Most of these systems have no problem operating at temperatures as low as 17°F with a few notable exceptions. One manufacturer (Mitsubishi) offers a system that can deliver 100% of its capacity at 0°F and still be able to supply 130°F indoor supply air at a -13°F outside temperature.

Heat pump efficiency is best rated using the HSPF - Heating Season Performance Factor. This is a ratio of how much electricity it will use over the entire heating season against how much heat it will produce for the same time period. With some systems now having HSPF ratings >10, the cost of operating the system is significantly less than even a high-efficiency gas furnace. For every 1kW of electrical energy the system uses, a modern air to air heat pump can produce more than 4kW of heat output compared to electric resistance heat, which is a 1:1 ratio of heat output to electrical input. Geothermal systems can get even higher ratios but require significantly more upfront investment, outdoor property and indoor space to install.

Equipment manufacturers have also made it a priority to make equipment that is compatible with existing systems. Many companies now produce indoor units that are close in size and layout to comparable gas furnaces so a conversion is a very straightforward process. If your home has a ducted forced-air heating system the cost of the equipment is often the greatest expense of an entire retrofit. Other benefits of these newer systems such as humidity control and inverter-driven compressors give the amazing benefit of being able to dry out the house on humid days and keep very stable temperatures since they do not operate in an on/off manner. Modern equipment also operates so quietly it is hard to tell if it is running even when standing next to it.

With the ability for homeowners to purchase 100% renewable electricity coupled with the technology and equipment to use that power in an extremely efficient way, heat pumps will hopefully soon be just as popular as electric cars have become and enable all of us to soften our own environmental impact.

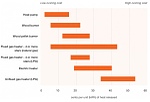

The picture on the right compares the running costs of different heating sources, with costs increasing as you move from left to right.